GrabCAD - Alstom Challenge Submission

Hi everyone!As promised I will make a post regarding Creating Machines submission on Alstom Engineering challenge promoted by GrabCAD !

This is the last day for ideas submission and a lot of cool stuff is already submitted!

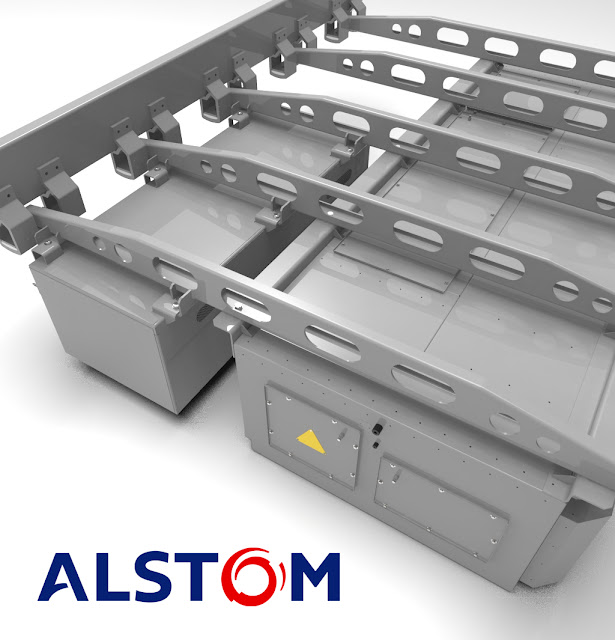

So, lets start explaining the main objective of the contest. The objective is to reduce the weight and the manufacturing cost of the CVS and battery box support that already exists on Metropolis City Train. You need to accomplish the Norms given (challenge´s attached documentation) and use only the available volume (restricted volume also in the attached documentation).

Now lets go to my idea.

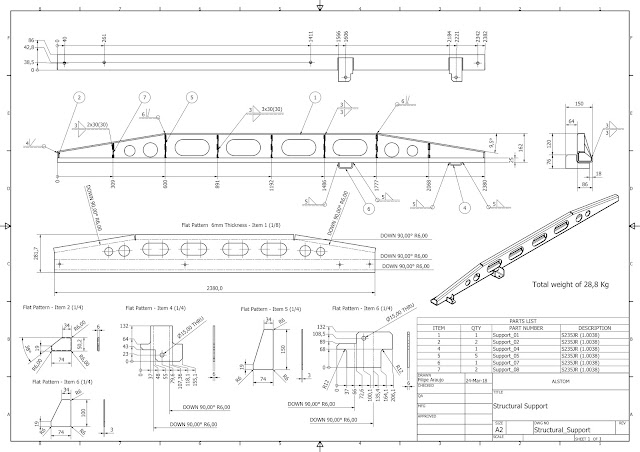

Every component is made of laser cutting sheet metal parts. The material can be normal S235JR Steel but for more resistance other materials can be used, for example S275J2G3 or S355J2G3 (1.0570).

The thickness of the main body is 6mm. Lower the thickness of the main body can surely be possible and lower the total weight can be achieved, but I really think that a total weight of 28,8kg is way better when compared to the actual support weight (56,5kg).

A complete set has a total of 144 kg (Alstom´s actual set has 282,5kg), there is no need to change the bolt joint support on the train solebar and it fits perfectly on the available volume.

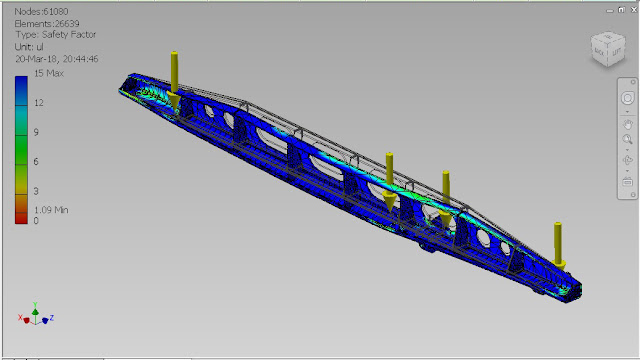

The design accomplishes the standard Norms (EN12663; EN61373; Alstom Standard ENG-STD-003; EN 45545-2).

Unfortunately, due to lack of time is impossible to present more variations to this design, but I’m extremely happy with this design in particular and with the overall result and I really believe that this structure is something that can be putted on practice and has a realistic vision on which design, safety and overall feasibility is concerned.

For more detailed information about the contest and to see other submissions go to: https://grabcad.com/challenges/redesign-the-structural-support-of-the-metropolis-metro-underframe

All 3D files are available for download here on Creating Machines, just go to the Downloads field on the very top of the Blog.

.png)

0 comentários: